Plant Protection Drones: Evolution in Progress - Making Plant Protection Simpler, More Efficient, and Safer

China is currently experiencing population aging and a trend of rural labor migration to cities. Compared with developed countries, domestic agricultural production efficiency is still much lower. The application of drones in the agricultural field will be the largest in scale, so Skyelectronic Intelligent has decided to apply drone technology to agricultural plant protection, making plant protection simpler, more efficient, and safer. Skyelectronic was established in 2015. After several years of development, the product line has expanded from 6L to 16L models, basically covering most application scenarios both domestically and internationally. It possesses core modules including: flight control systems, high-precision navigation systems, intelligent spraying systems, backend management systems, etc., making it a technology company in the drone field that independently researches and develops a complete set of core systems and focuses on plant protection.

China’s cultivated land area is 2.025 billion mu (approximately 135 million hectares), with nearly 300 million agricultural population. The per capita cultivated land area is less than 7 mu (approximately 0.47 hectares). Due to urbanization progress in recent years, rural labor has accelerated migration to cities, so the actual per capita cultivated land area is somewhat larger, roughly between 7-15 mu (0.47-1 hectare). We predict that within the next 10 years, China’s per capita cultivated land area will exceed Japan’s per capita 30 mu (2 hectares). China has vast territory, with both large farms similar to those in the United States and small farmlands similar to those in Japan. Therefore, electric multi-rotor drones, with their advantages of low cost, easy operation, convenient transportation, and easy maintenance, are better suited to handle these complex and diverse application scenarios in China.

After several years of development, electric multi-rotor drones have gained recognition from a wide range of users. At the same time, they have received corresponding support at the national policy level. Currently, in more than 70% of provinces, plant protection drone purchasers can enjoy a certain proportion of government subsidies. In 2019, domestic aerial pesticide application area was approximately 3%. We believe this proportion will increase to at least 50% in the future, and at least 70% in rice-growing areas.

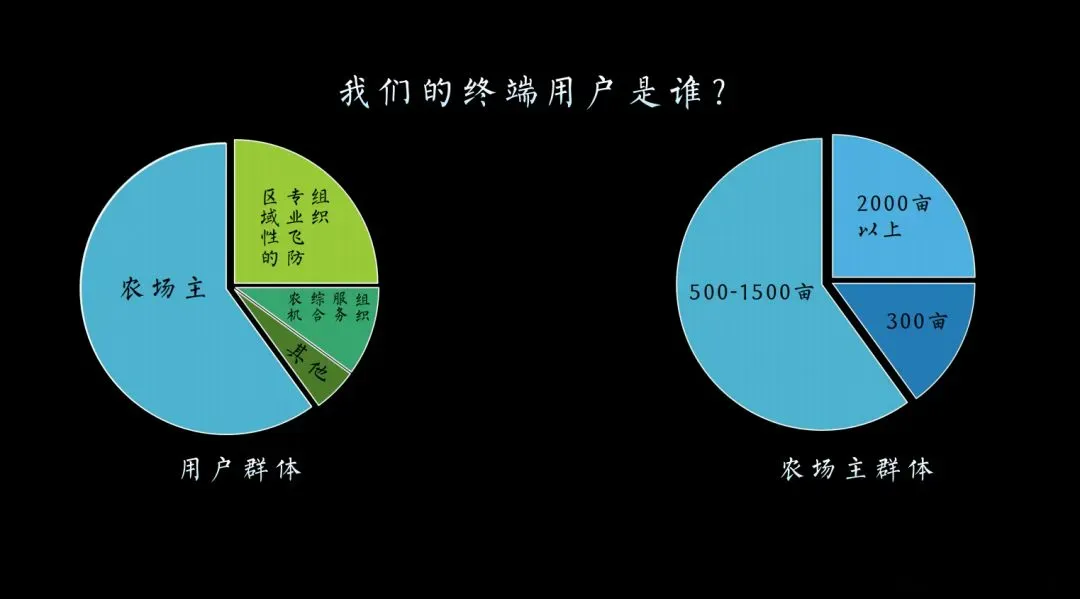

Based on such a market, who are our end users? We have divided them into the following groups: farm owners, regional professional aerial application organizations, and comprehensive agricultural machinery service organizations.

Farm Owners: Because plant protection is highly time-sensitive, for most farm owners, during the plant protection operation period, pesticides need to be applied within three to four days. Rather than waiting for other service organizations or other farm owners to finish their own land before providing service, it’s better to purchase equipment and carry out operations themselves. Moreover, farm owners already have various agricultural machinery such as tractors, harvesters, rice transplanters, dryers, etc. Adding a plant protection machine doesn’t require additional operator costs. At the same time, with the popularization of drones, machine costs will further decrease, as can be seen from this year’s situation. Therefore, we believe this user group has the largest proportion.

Regional Professional Aerial Application Organizations: Here we need to emphasize the words “regional” and “professional.” Regional represents local, and professional represents understanding pesticide usage. We believe these users are transformed from local pesticide dealers. Their future business model of providing pesticides, services, and accounts receivable will leave other aerial application teams with single business models no room for survival. Therefore, they will occupy a certain proportion.

Comprehensive Agricultural Machinery Service Organizations: Because this group already possesses service capabilities and customer resources for various other agricultural machinery, adding drone plant protection services won’t increase additional management costs or market expansion costs for them. Therefore, they will also occupy a certain proportion.

We further divide the largest proportion of farm owners into three smaller groups: around 300 mu (20 hectares), between 500 to 1500 mu (33-100 hectares), and above 2000 mu (133 hectares). The country hopes to improve agricultural production efficiency through land transfer concentration, so small farm owners will gradually be phased out. Additionally, both the speed of land transfer and rural labor migration are gradual processes, so in the short term, a large farm pattern similar to that in the United States won’t form. We believe most future farm owners will be concentrated in the range of 500 to 1500 mu (33-100 hectares).

Based on these user groups, we believe plant protection drones should possess the following three attributes: agricultural machinery attributes, technological attributes, and internet and big data attributes.

Agricultural Machinery Attributes: Essentially, it is a type of agricultural machinery. As an operational tool, stability and efficiency are paramount. The pesticide application period is about three to four days. Once a user’s equipment encounters problems in the field, local channels need to respond quickly to solve the problem. At the same time, because there are agricultural machinery purchase subsidies, agricultural machinery channels have greater advantages compared to other channels.

Technological Attributes: Plant protection drones can be considered relatively complex operational tools. The entire machine includes control systems, high-precision navigation systems, intelligent spraying systems, backend management systems, etc. To create better products and meet customers’ new needs faster, we believe independent research and development of core systems is necessary. Self-developed core systems can give equipment good technological extensibility. For example, powder sprayers, mist sprayers, fertilizer spreaders, etc., can be better installed on existing plant protection machines. Another example is that we can better apply the aircraft’s RTK module to RTK mobile base stations or fixed base stations. Furthermore, plant protection management backends can be connected to field pest monitoring systems, meteorological monitoring systems, soil monitoring systems, etc. These technological extensions can reduce plant protection costs from other perspectives and improve plant protection efficiency and effectiveness.

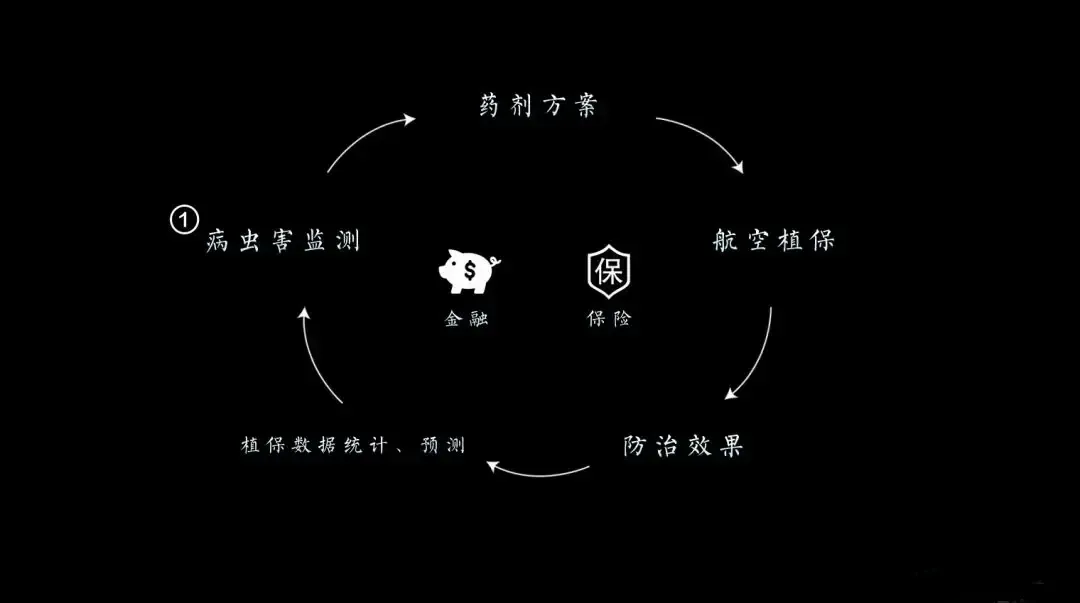

Internet and Big Data Attributes: This is an attribute that gradually becomes prominent in the middle and later stages of the market. With the diversification of plant protection drone application scenarios and the specialization of aerial pesticides, future end users will tend more to obtain aircraft and matching pesticide solutions. We believe plant protection drone management platforms can solve the matching, transaction, and distribution problems of aerial pesticides, manage field pest data, meteorological data, pesticide usage data, as well as flight speed, height, spacing, spraying flow rate, etc., during plant protection drone operations. With these data, we can have precise statistics and predictions of farmland health status and future yields. Through the entire plant protection system, users can enjoy faster, lower-cost insurance and financial services.

Skyelectronic Intelligent always prioritizes creating more stable and durable products as its primary goal.

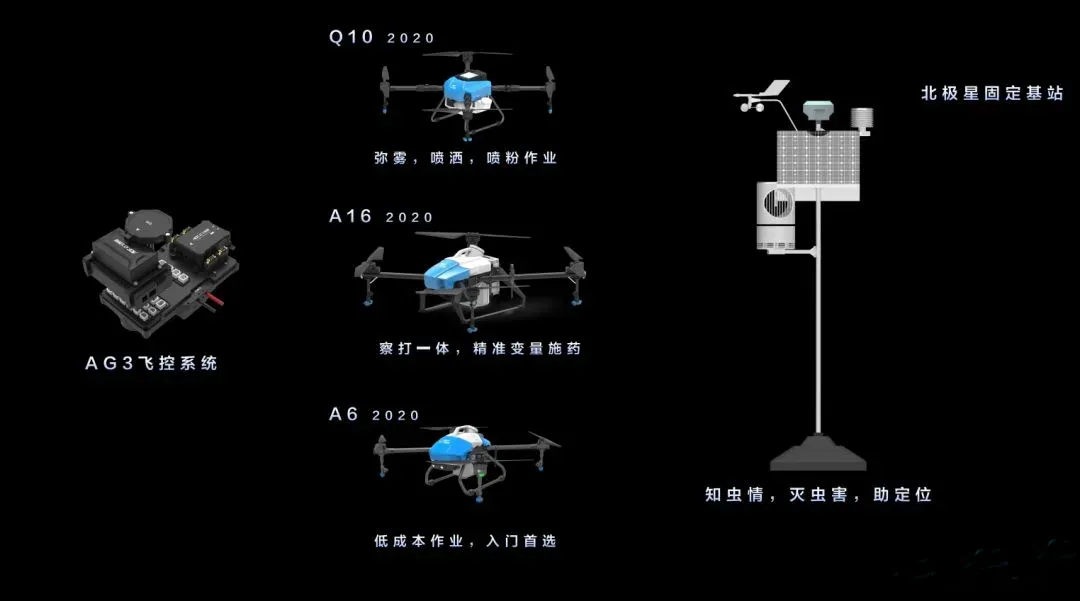

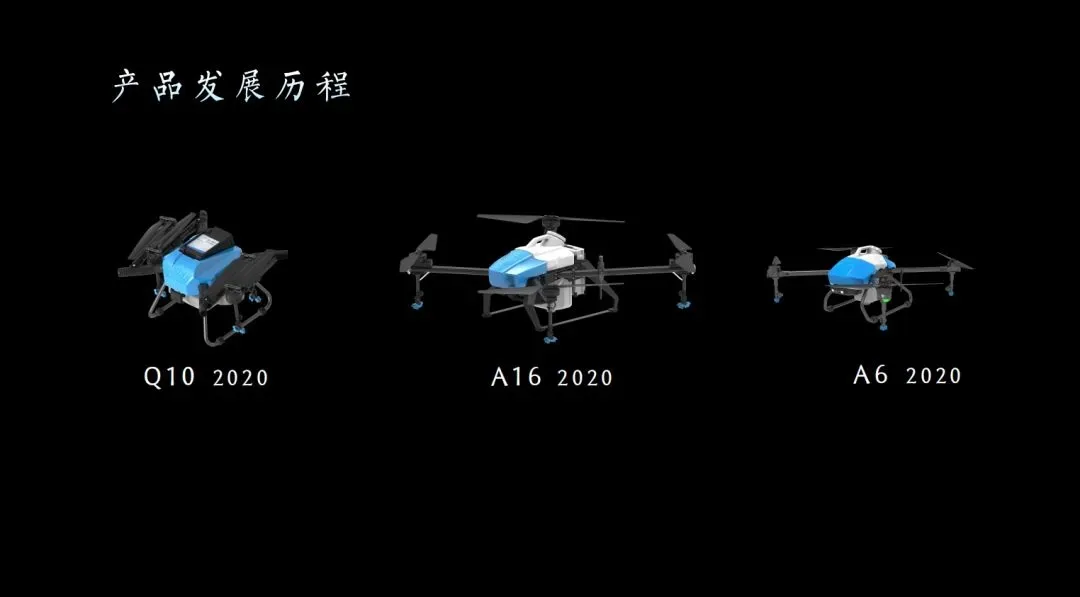

This year, we launched the new generation Q10 2020, which adds folding functionality while improving many details. The Q10 2020 combines stable durability with portability and speed, making it the brand product with the highest cost-performance ratio on the market. For large plots, we launched the more stable and efficient A16 2020. For complex small plots, we launched the more portable A6.

These three models can basically cover most application scenarios both domestically and internationally.

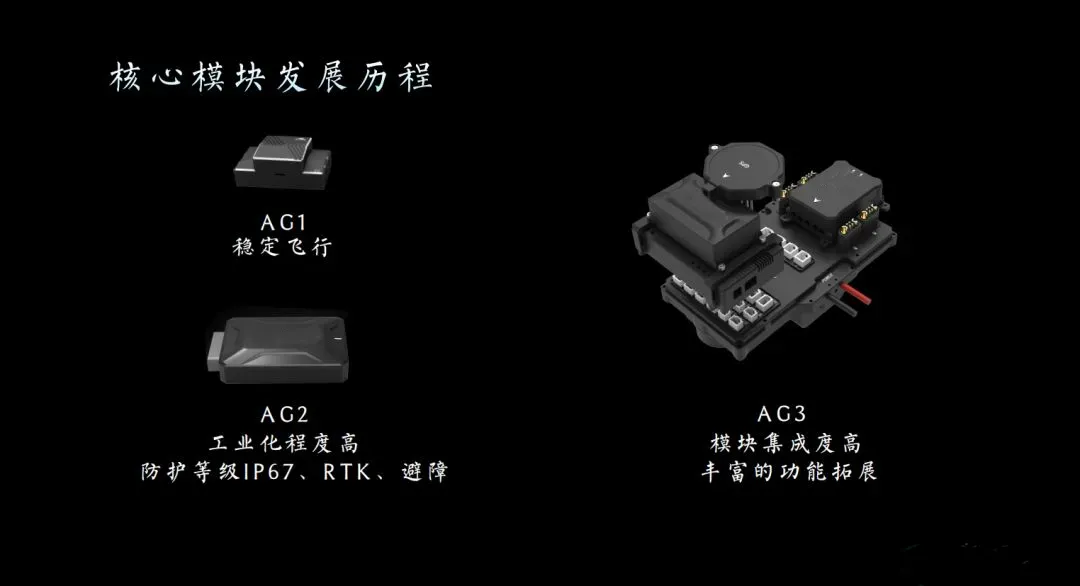

Skyelectronic’s control systems have undergone three generations of development.

The 1st generation flight control system underwent at least 50,000 flight tests and can achieve stable manual, semi-automatic, and fully automatic flight.

Later, we launched the 2nd generation control system, which improved industrialization level based on the previous generation, with protection level reaching IP67. It can be equipped with RTK modules and obstacle avoidance modules. This generation of flight control system was launched in the A16 2019 in domestic and international markets. After more than a year, it has accumulated at least 15 million mu (1 million hectares) of field operation data domestically and internationally.

This year, we launched the new generation AG3, which improved module integration based on the previous generation, adopting a design concept similar to computer motherboards, eliminating many wiring harnesses between modules, greatly speeding up installation and maintenance. In terms of software: it supports online upgrades and online fault diagnosis, supports access to field meteorological monitoring data, pest monitoring data, soil monitoring data, supports third-party prescription map import and calculation, etc.

To better solve plant protection problems, Skyelectronic Intelligent also launched a field pest detection system connected to the drone management backend this year. This system can reduce the number of times users need to go to the field to check pest conditions and can also help users confirm plant protection effectiveness after pesticide application.

After reading the above content, I believe everyone has gained a deeper understanding of drone plant protection.

We believe that in the future, to do plant protection well, simply making a pesticide-spraying drone is far from enough. We also need to tell users when to apply pesticides, what to use, and how effective the application was.

Based on these needs, we envisioned a scenario: During the operation period, through the pest monitoring system, we see the types of pests and their rising trends in the backend. At the same time, corresponding pesticide manufacturers provide pesticide solutions for plant protection operations through our plant protection management backend. After obtaining the pesticides, we take the drone and pesticides to carry out aerial plant protection operations. Afterwards, we can see the daily declining pest data in the backend until it stabilizes, confirming control effectiveness.

With this complete set of pesticide usage data and plant protection operation data, we can have good statistics and predictions of farmland health status and future yields. Through this plant protection system, users can enjoy faster, lower-cost insurance services and financial services. Thereby making plant protection simpler, more efficient, and safer.

Hangzhou Skyelectronic Intelligent Technology Co., Ltd. was established in 2015, with its headquarters located in the Hangzhou High-tech Enterprise Incubation Park. It is a high-end equipment supplier covering complete plant protection drone solutions, flight control systems, RTK high-precision navigation systems, intelligent spraying systems, agricultural Internet of Things, and green prevention and control systems. R&D personnel come from professional research institutes of aerospace groups, military enterprises, University of Science and Technology of China, and other research institutes and universities, with nearly 10 years of industry experience. Current complete models include A6 plant protection drone, A10 plant protection drone, Q10 plant protection drone, and A16 plant protection drone. Skyelectronic Intelligent leads the industry into the true era of smart agriculture.